Liberty Precision’s Approach to Agile Manufacturing, Built for Aerospace and Defense Demands

In industries where timelines are tight and failure is not an option, agile manufacturing is a necessity. At Liberty Precision, this mindset is championed from the top down, led by CEO Bill Berrien, whose focus on adaptability and continuous improvement has shaped how the company responds to shifting market demands.

Serving aerospace and defense customers means operating in an environment defined by urgency and precision. Liberty Precision’s approach to agile manufacturing ensures we can pivot quickly, scale responsibly, and deliver uncompromising quality, no matter how complex the challenge.

Defining Agile Manufacturing in a Precision Machine Shop

At Liberty Precision, agile manufacturing is the ability to respond rapidly without introducing risk. That balance is especially critical for a precision machine shop supporting aerospace manufacturing and defense programs, where compliance, traceability, and repeatability are non-negotiable.

Agility doesn’t come from speed alone. It comes from experienced teams, well-defined processes, advanced equipment, and digital systems that keep every department aligned. Liberty’s ability to adapt is rooted in preparation, with the capacity and infrastructure ready before demand spikes.

Responding to Industry Shifts with Confidence

Pivoting to support aerospace and defense growth

As aerospace and defense demand accelerated in recent years, Liberty Precision leaned into its agile manufacturing foundation. Beginning in 2024, the team actively expanded its focus on defense and munitions work, connecting with OEMs and program leaders through industry events like the SHOT Show.

These programs often involve extremely tight tolerances and repeatability at high volumes. In many cases, a single nonconforming part can trigger costly sorting or delays. That’s why Liberty’s systems are designed to prevent that risk through consistency at scale.

Precision at volume

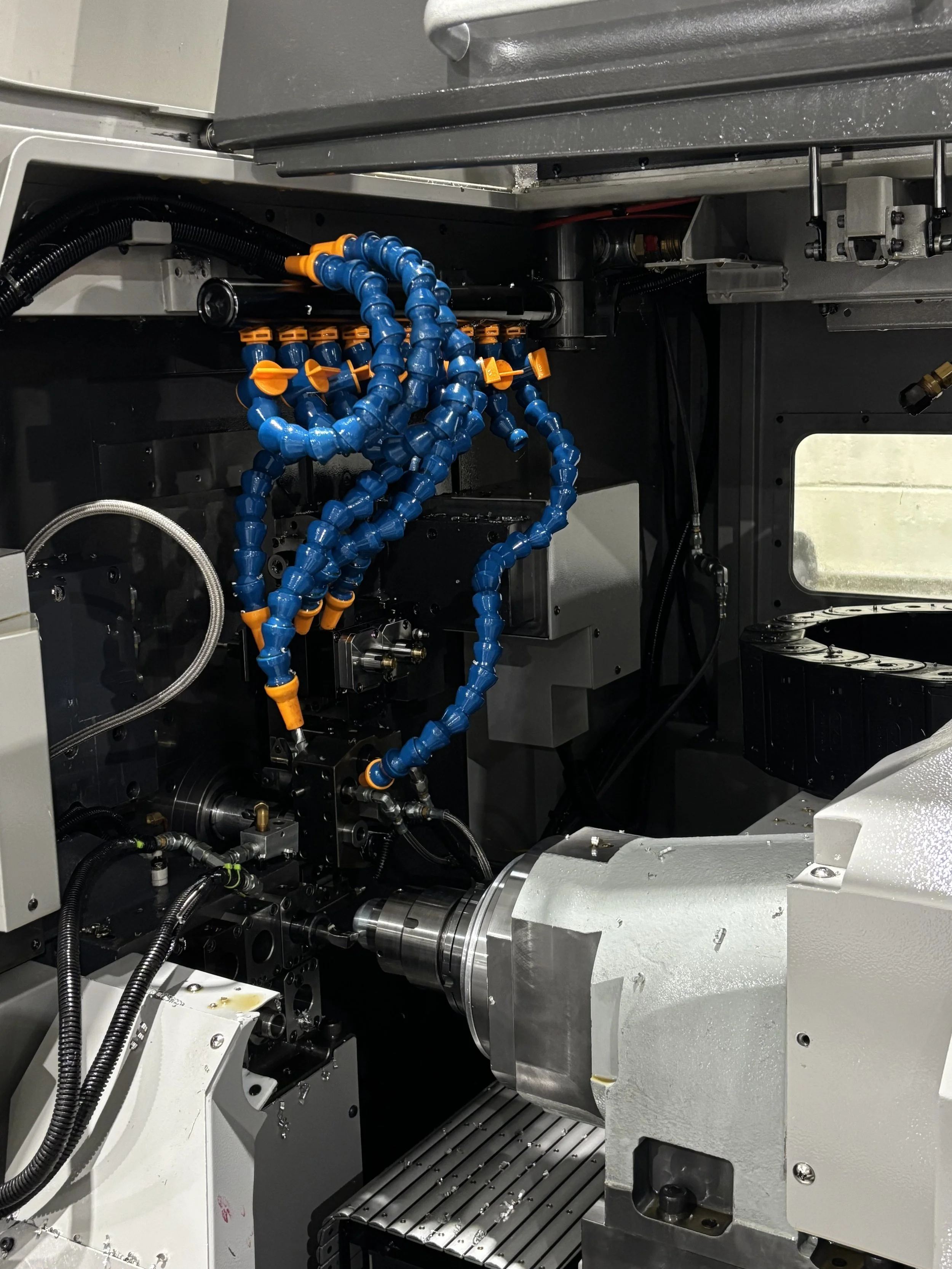

Liberty Precision supports these programs through advanced CNC milling services and Swiss machining services. By completing complex components in fewer operations and controlling every step of the process, the team delivers predictable results for high-stakes applications.

Machine-mounted scales, advanced inspection equipment, and process documentation ensure that parts come off the machine the same way every time.

What Enables Liberty’s Agile Manufacturing Model

Skilled teams and programming depth

Agility begins with people. Liberty Precision invests heavily in training and cross-functional expertise, ensuring multiple team members can program and run complex jobs. This depth eliminates bottlenecks and allows work to move quickly through the shop, even when priorities change.

This programming strength supports complex machining across a wide range of geometries and materials, helping customers accelerate timelines without sacrificing accuracy.

Processes that scale without risk

Liberty operates as an AS9100D-certified machine shop, with internal processes designed to protect customer data and maintain compliance. These systems allow Liberty to move swiftly while preserving the discipline required for defense and munitions work.

Digital tools that keep work moving

Technology plays a central role in Liberty’s agile manufacturing strategy, with systems like:

Paperless Parts enables faster, more accurate quoting.

Hexagon ESPRIT accelerates CAM programming.

HighQA streamlines quality documentation.

MachineMetrics provides real-time visibility into machine utilization.

UiPath automation eliminates hours of manual reporting each day.

Together, these tools strengthen the digital thread, allowing decisions to be made quickly and confidently.

Solving problems in real time

In-house 3D printing allows Liberty’s teams to design custom fixtures and inspection aids on demand. These solutions reduce handling time, speed up sorting, and remove inefficiencies, often cutting process time by more than half.

Communication That Keeps Production Aligned

Agility depends on clarity. Liberty Precision emphasizes open communication with customers, vendors, and internal teams to ensure tooling, materials, programs, and capacity stay aligned. Shop-floor dashboards provide a single source of truth, keeping production synchronized and proactive.

Agile Manufacturing When It Matters Most

At Liberty Precision, agile manufacturing is built into how we operate, allowing us to support defense and munitions customers with speed and precision. No matter the complexity, Liberty is equipped to adapt without compromise.

When your program demands flexibility backed by discipline, Liberty Precision is ready to deliver. Request a quote to partner with our highly skilled team.