Liberty Precision Leads the Way in CNC Milling and CNC Turning Services

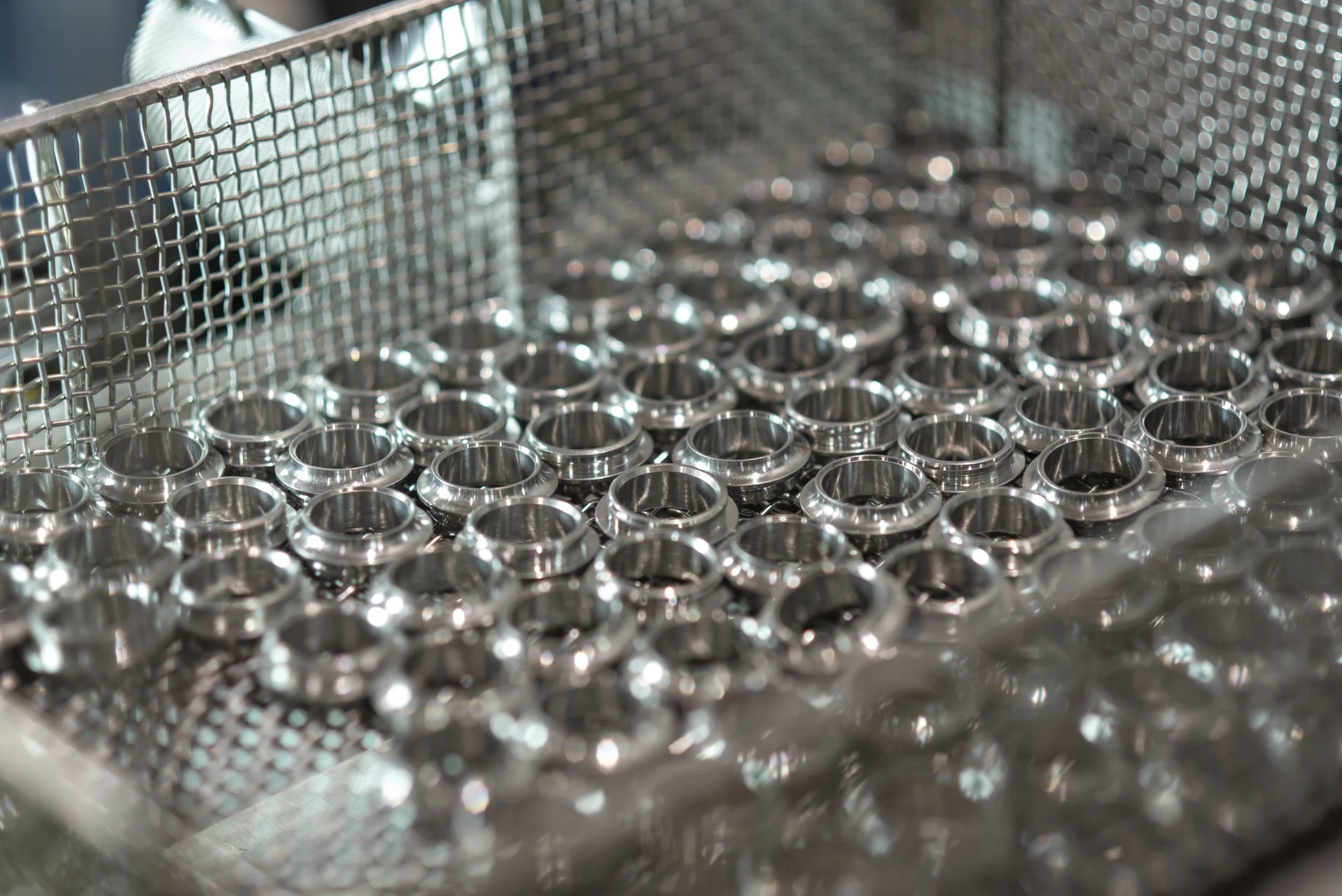

When you’re manufacturing for aerospace and other high-stakes industries, precision and speed are critical. At Liberty Precision, our commitment to innovation and technical excellence sets us apart as a trusted partner for CNC milling services and CNC turning services across a range of demanding sectors.

From aerospace machining services to high-volume commercial work, our team is built to take on the most challenging projects with agility, accuracy, and speed.

A Culture of Complexity

Complex part geometries and tight tolerances are part of the daily routine at Liberty. But what truly sets us apart is our people. Our machinists and engineers bring a deep understanding of precision CNC machining services, honed over years of experience. Many of our team members are cross-trained across different machines and disciplines, which allows them to pivot between jobs seamlessly and solve problems before they arise.

In a recent example, we supported a defense OEM facing major delays due to supplier challenges. They needed critical components machined within a two-week window. Our team responded with lightning speed by preparing tooling, programming machines, and executing a multi-operation job with full inspection well ahead of schedule.

Agile Operations for a Demanding Market

At Liberty Precision, we’ve developed a workflow model that blends flexibility with control. Our shop floor operates with standardized setups, so programs and processes can be replicated quickly across machines. This not only reduces training time but also improves output and consistency.

Whether you require multi-axis machining services or repeat production of legacy parts, our approach allows us to switch between jobs without downtime. Our facility is optimized to meet the demands of industries like defense and munitions, where lead times are tight, requirements are strict, and nothing short of perfection will do.

Advanced Equipment, Backed by Smart Systems

We invest heavily in best-in-class technology to deliver outstanding results through both our CNC turning services and CNC milling services. Key pieces of equipment include our vertical milling center and turning center by Doosan, which have high-speed spindles and automated touch-probe systems for real-time feedback. Our lineup also features live-tool lathes that enable complete parts to be machined in a single setup.

These investments, among others, allow us to consistently hit tight tolerances, whether we’re delivering low-volume prototype components or tens of thousands of production parts.

Certified for Critical Applications

As an AS9100D-certified machine shop, Liberty Precision upholds the strictest quality standards required by the aerospace and defense sectors. Our quality team collaborates closely with machinists and engineers to ensure that every part that leaves our facility meets your specifications.

Supporting the Next Generation of Talent

A successful shop is only as strong as its people. That’s why we pair our technical capabilities with a strong focus on workforce development. Through mentorship, on-the-job training, and a culture of continuous improvement, we’re preparing the next generation of machinists to move the industry forward.

Your Go-To Partner for CNC Milling and Turning

Whether you’re building cutting-edge aerospace systems or developing commercial products that require extreme precision, Liberty Precision is the partner you can count on for fast, flexible, and high-quality results.

Let’s discuss how our approach to CNC turning services and CNC milling services can support your most complex projects. Reach out to our team to learn how Liberty Precision brings reliability, speed, and quality to every job we take on.